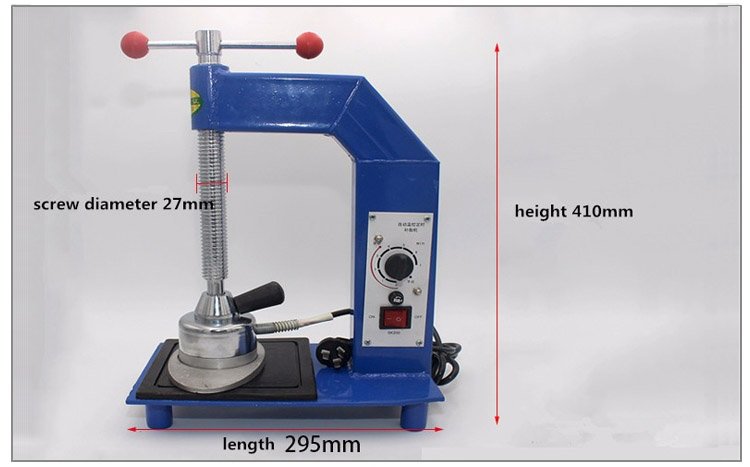

Hot pneumatic temperature-control timing tyre vulcanizing machine

Control timing tyre vulcanizing machine Adjustable: An adjustable, rotating C-frame cavity simplifies loading and unloading tires while maximizing stability.

Control timing tyre vulcanizing machine Simple one-man operation. Repairs tread, shoulder and sidewall.

Control timing tyre vulcanizing machine

Data of Control timing tyre vulcanizing machine

| Product name | control timing tyre vulcanizing machine |

| Material | steel |

| input voltage | 220V |

| input power | 500W |

| temperature scope | 145-165℃ |

| repair Area | 60*60 mm |

| Application | for inner tyres, mini size bias tyres and tubeless tyres |

| Single size | 345*190*390 mm |

| packing | 4 sets tire repair vulcanizer machine one carton |

| color | blue, red, and other according to the requirement of customers |

Control timing tyre vulcanizing machine feature

Control timing tyre vulcanizing machine Tire repair method

1. Clean the wound surface where the tire needs to be repaired and mark it.

2、Use a grinding machine to grind the surface of the wound, the area is slightly larger than the wound。

3、Use the brush for raw rubber and gasoline by mixing good mortar (or hot glue) evenly coated on the polishing.。

4. Cut the appropriate size of the rubber, it will fill the wound,

5、Press the hot head on the raw rubber (if possible you can fill a thin layer of aluminum or iron on the raw rubber), try to place the wound on the central heating head, pressing the screw, the tires fixed.

6. Turn on the timer switch and put it in the right place, cold start can refer to "20" (or adjust the vulcanization time according to the temperature and condition of the wound), heat start time It can be a little shorter, if you don't need timing it can be set to manual gear, then the hot head to work.

7、At the end of vulcanization, the tire repair machine automatically cut off the hot head of the power supply.

Control timing tyre vulcanizing machine Precautions

1. The power cord must be safely grounded, the power supply is preferably provided with a leakage protection switch, you must turn off the power when replacing the fuse.

2. Handle with care when removing the hot head, to avoid burns.

3. If it is necessary to fill the elongated wound tube, to be equipped with an oval plate, while it is marked with small eyes at both ends of the wound to prevent cracking inflated leak.

5. After the head, if you use hot sticky dirt, use sand to polish the clean skin, otherwise it will affect the flatness of the tire and smoothness.