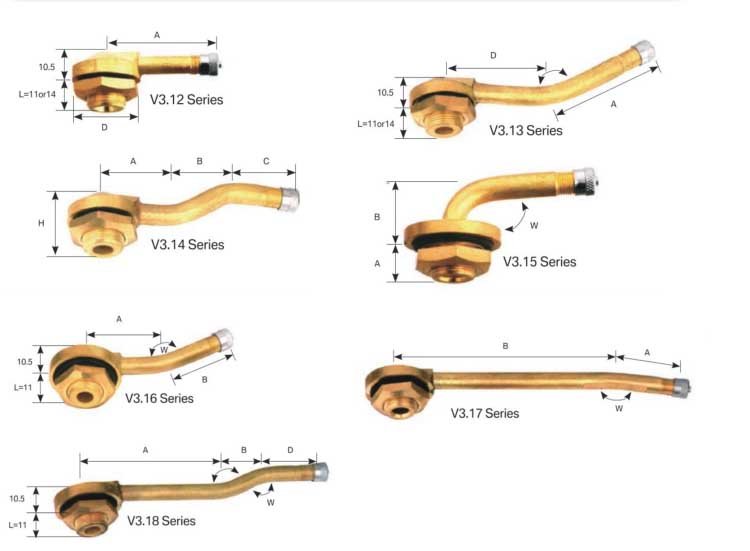

Product information "Valves - Clamp-on, Assembly, Truck"

Rim valves for tubeless truck tires - recessed rims

| TR NO. | A | B | C- | D | W° | H |

| V3.12.1 | 40 | - | - | - | - | - |

| V3.12.2 | 95 | - | - | - | - | - |

| V3.13.1 | 42.5 | - | - | 46.5 | 153 | - |

| V3.13.2 | 79 | - | - | 30 | 126 | - |

| V3.14.1 | 25 | 21.5 | 24.5 | - | - | 21 |

| V3.14.2 | 45 | 21.5 | 24.5 | - | - | 21 |

| V3.14.3 | 37 | 21.5 | 24.5 | - | - | 21 |

| V3.15.1 | 14 | 22.5 | - | - | 110 | - |

| V3.15.2 | 11 | 15.5 | - | - | 95 | - |

| V3.16.1 | 36 | 29 | - | - | 150 | - |

| V3.17.1 | 99 | 31.5 | - | - | 172 | - |

| V3.17.2 | 116 | 31.5 | - | - | 172 | - |

| V3.18.1 | 64 | 24.5 | - | 14.5 | 146 | - |

| V3.18.2 | 81 | 24.5 | - | 14.5 | 146 | - |

| V3.18.4 | 51 | 37.5 | - | 19.5 | 138 | - |

| V3.18.5 | 68 | -37.5 | - | 19.5 | 138 | - |

When should metal tire valves be replaced? It's always best to do so every time the tire is changed!

Metal valves are subjected to enormous stress during their service life and are subject to many different environmental influences. These include varying degrees of ozone, solar radiation and the use of chemicals. It doesn't matter whether it's a car tire valve, a truck or a bicycle, or what it's made of (rubber or metal).

Therefore, every time you change a tire in the workshop, not only the tire and rim should be checked and tested, but also the valve. Only by regularly checking the rim valves can you guarantee a safe driving experience. Defective metal or rubber valves can lead to potential tire pressure loss. In addition, external damage to the rim valve or corrosion of the valve core can also lead to a flat tire.

The consequences of a loss of tire pressure include various safety risks, the less dangerous of which include increased tire wear, increased rolling resistance and increased fuel consumption. However, a cracked metal tire valve can increase braking distances and can lead to unsafe driving with the risk of losing control of the vehicle.

To minimize safety risks and get the best driving experience, we recommend that you regularly check and replace tire valves and rim valves.