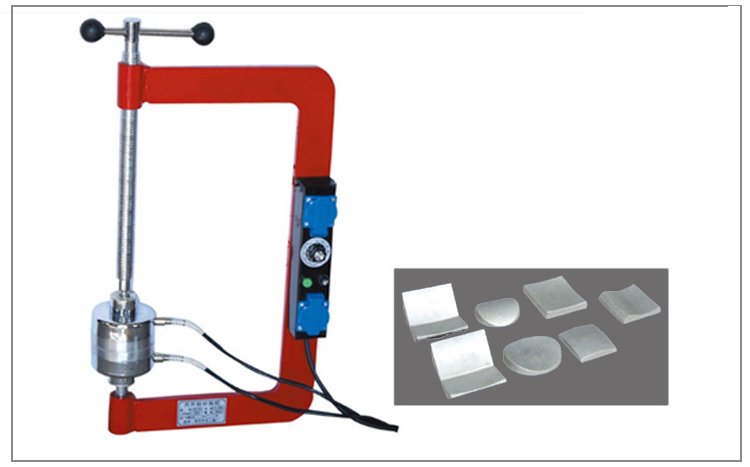

Tyre Vulcanizing Machine

Tyre Vulcanizing Machine Simple one-man operation repairs tread, shoulder and sidewall, large capacity, fully rotating C-frame fits different wheel sizes and allows for vertical or horizontal repairs

Tyre Vulcanizing Machine Lightweight, self-contained design that offers portability and maximum stability

Tyre Vulcanizing Machine Parameters :

- Voltage:220v

- Power:550w×2

- Temperature Range: 145-165(℃)

- Repair Area:100x80m㎡

- GW:23kg

- NW:21kg

- Packing Size:685*385*180mm

Tyre Vulcanizing Machine

1.Temperature control: Vulcanization temperature between 120°C and 180°C. Constantly controlled heating elements maintain an optimal temperature.

2.6 sets of molds: 6 molds that fully meet the needs of tire repair in any position (such as shoulder, crown and sidewall), just select the corresponding mold.

3.Timing: automatic/manual two modes, timing range 0-60 minutes.

4.Detachable and slideable screw handle: The point of force application can be changed as needed, which saves more labor.

5.Tire vulcanizing machine: The body of the tire repair machine is made of thick plate, which is sturdy and durable. The tire repair machine owns an adjustable and rotating C-frame cavity that simplifies tire loading and unloading while maximizing stability, the height tower can also be adjusted.

Tyre Vulcanizing Machine Description:

1. Simple one-man operation.

2. Repair the tread, shoulder and sidewall.

3. Large capacity fully rotating C-frame fits different wheel sizes and allows for vertical or horizontal repairs.

4. The vulcanization repair process cures the patch and inner tire liner to form a dense and sealed repair job.

5. An adjustable and rotating C-frame cavity simplifies tire loading and unloading while maximizing stability.

6. Adjustable height tower.

7. Contoured inner and outer curing heads fit a variety of tire profiles.

8. Long-lasting Acme thread hand wheel bolt applies over 4,000 lbs. of pressure and heat for maximum adhesion of the patch to the casing.

9. Energy and profitability to reduce operating costs.

10. Lightweight, free-standing design offers portability and maximum stability.

11. Does not require time-consuming tension straps.

12. Handles long side wall repairs.

13. Cure both patch and plug at the same time.

14. Curing heads can be operated individually or simultaneously for maximum repair efficiency.

15. Constant controlled heating elements maintain optimal temperature.

Tyre Vulcanizing Machine Tire repair method:

1. Clean the wound surface where the tire needs to be repaired and mark it.

2. Use a grinding machine to grind the surface of the wound, the area is slightly larger than the wound.

3. Use the brush to mix raw rubber and gasoline with good mortar (or hot glue) evenly coated on the polishing.

4. Cut the appropriate size of the rubber, it will fill the wound.

5. Press the hot head on raw rubber (if possible, you can fill a thin layer of aluminum or iron on the