What are different types of jacks?

Lifting jacks are used for leveling or positioning heavy equipment, lifting automobiles and for supporting structures. They typically use screw or cylinder-based actuators and are powered by hydraulic, mechanical, electric, or manual methods.

Lifting jacks are a basic tool of industry and are especially common in automotive applications. Lifting a car with its stock lifting jack to change a tire is the most common application. Other uses include:

- Raising and leveling steel girders on their footings or vertical columns

- Leveling and positioning heavy machinery in a machine shop or manufacturing facility

- Lifting and positioning heavy pieces of metal stock or other materials

There are multitudes of uses where heavy objects have to be raised using some basic mechanic principle such as hydraulic, pneumatic, inclined plane or mechanical screw. This is where long distance acting on a light force translates into lifting up a heavy force up a short distance.

Types

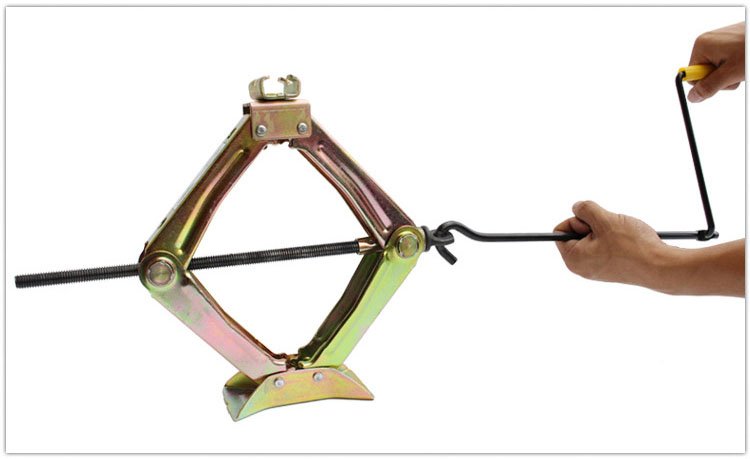

There are many different types of lifting jacks including bottle jacks, floor jacks, ratchet jacks, scissor jacks and others.

Bottle Jacks

These are simple hydraulic lever jacks that use a mechanical advantage of high pressure small diameter piston, or the master, pumping fluid into a large diameter piston’s chamber or the slave cylinder. The two are mounted next to each other on the base. The master is usually pumped up and down by a simple lever that often doubles as the wrench that operates the release valve. They have a simple round saddle on top and a rectangular cast iron base. They are used mainly for vehicles but they have many applications otherwise, being so simple and small.

Ratchet jacks use the ratchet and pawl mechanism that cause a rotary gear to move up or down a linear track. The ratchet pawls keep the gear from slipping back down under load and causing the jack to fail. The old traditional bumper jack in older American cars was a ratchet style jack. But they are not very safe and are heavy. So for those reasons they have been superseded by scissor jacks as standard equipment on most vehicles. They are still used in industry for lifting lighter pieces.

These are simple jacks that have four linked vertical arms. Between each of the two pairs of vertical arms there is a female threaded piece where the jack’s screw goes through. The jack is raised or lowered by rotating the operating screw. These are usually found in a car trunk as a tire changing tool due to its compact size.

These are the workhorses of the vehicle repair world, noted and prized for their safety, strength, convenience and capacity. They work on a similar principle as a bottle jack, but they are mounted on a 4 or 6 wheeled carriages that have swivel castors in the rear and fixed cast wheels in the front. They have a large round saddle that can be removed easily and replaced with different sizes or custom saddles and shoes. The pump lever is also the way you pull and move the jack around. The lever also acts as its release valve actuator by rotating the handle. Floor jacks have a low initial clearance so they can get under a low car then safely jack it up.

Wheel and Shop Bumper Jacks

These are large roll around floor jacks that can lift a whole vehicle up by the front or the rear by cradling the wheels or pushing up on the front of the frame. They have a floor carriage and a large vertical gantry that holds the piston. They are usually hydraulic powered and are popular in small repair shops where a built-in lift is too expensive.