Steel wheel weight RFQs

Frequently Asked Questions about Steel wheel weights

I. Questions related to quality and precision

1. How high is the precision of Steel wheel weights?

Generally, the precision of high-quality steel wheel weights can reach ±1 - 2 grams. This is because they are made by precision mold casting or machining during the production process. For example, in the balance correction of automobile tires, such precision can effectively reduce the vibration of tires when they rotate at high speed. However, some low-quality products may have poor precision, and the error may reach ±5 grams or even higher.

2. How to judge the quality of steel wheel weights?

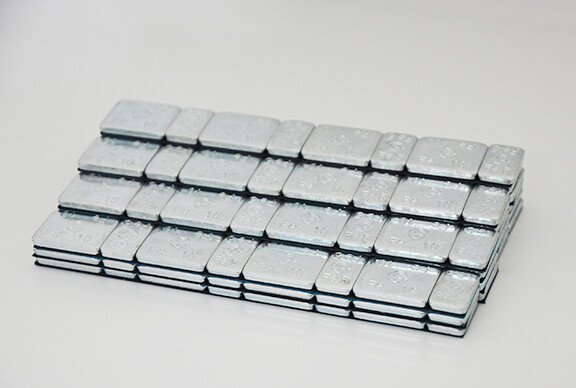

First, you can look at the appearance. A good quality steel wheel weights has a smooth surface without obvious burrs, cracks or rust. Because these defects may affect the uniformity of its weight distribution. Secondly, check whether its weight marking is clear and accurate. Wheel weights produced by regular manufacturers will be strictly marked with weights according to standards, and there will be strict quality control during the production process. In addition, professional weighing equipment can be used to detect whether its actual weight is consistent with the marked weight.

II, installation and use issues

1. Where is the steel wheel weights installed on the tire?

For car tires, the steel wheel weights is usually installed on the edge of the rim. It can be installed on the inside and outside, and the specific location depends on the imbalance point of the tire. Generally, a special balancing machine is used to detect the imbalance position and weight of the tire, and then the wheel weight is pasted or fixed with a clip to the corresponding position. For example, in a dynamic balance test, if more wheel weight is required on the outside of the tire, the wheel weight will be installed on the outer edge of the rim.

2. What are the precautions for installing steel wheel weights?

Before installation, make sure that the rim surface is clean, dry, and free of oil or dust, so as to ensure the adhesion or fixing effect of the wheel balance weight. If it is an adhesive wheel weights, pay attention to the temperature conditions of the paste. It is generally recommended to paste it at room temperature, and press it appropriately after pasting to ensure that it is firmly pasted. If it is a clip-on wheel weight, make sure that the clip is firmly installed and will not loosen or fall off during the vehicle's driving. At the same time, during installation, pay attention to the balance weight not interfering with the tire or brake parts.

3.Can steel wheel weights be reused?

If the wheel balance weight is not damaged and the weight accuracy still meets the requirements, it can be reused. For example, when the tire size is changed but the rim remains unchanged, the original balance weight can be removed and re-balanced and used again. However, be careful during the removal process to avoid damaging the wheel balance weight or rim. If the wheel weight is severely rusted or deformed during the removal process, it is not recommended to use it again, because this may affect its weight accuracy and installation effect.

III. Durability and maintenance issues

1. Are steel wheel weights prone to rust?

Steel wheel weights are prone to rust in a humid environment. This is because iron reacts chemically with oxygen and moisture in the air to generate rust. To prevent rust, some wheel weights are galvanized or painted. However, if these protective layers are damaged during use, such as scratches during installation or vehicle driving, the risk of rust will increase. The wheel weight of the rusted weight may change, affecting its balancing effect.

2. How to maintain Steel wheel weights?

Check the appearance of the wheel weights regularly for signs of rust or damage. If slight rust is found, use sandpaper to gently polish it and then apply anti-rust paint. For adhesive wheel weights, also check whether the adhesive is firmly attached. When washing the vehicle, try to avoid using highly corrosive detergents to spray directly on the weights to avoid damaging their surface protective layer.