Fe Wheel Balance Weight type

Wheel weights are used to correct and counteract those imbalances found when balancing tire assemblies. By applying the weights to the wheel in the appropriate location, the addition of the targeted added weight causes the wheel’s mass to be equally distributed around the axis of rotation. This ensures the wheel will rotate without vibration.

Because lead is toxic and pollutes the environment, some countries and regions have banned the sale of lead balance weights. Compared with zinc, the price of iron is lower than that of zinc, so now more and more wheel balance weights are made of iron. qualitative substitution.

Steel and zinc have become the leading alternatives for lead wheel weights, but steel has become a better choice than zinc for these six reasons:

1. Greater Accuracy

Porosity occurs during the casting process when pockets of air are trapped inside the wheel weight body, making zinc wheel weights lighter than designed and leading to inconsistent weight based on accepted industry standards. Shengshiweiye wheel weights are formed from a solid piece of steel rather than cast in a mold. That means zero porosity and results in a more accurate balance done right the first time, every time.

2.Environmentally Friendly

The EPA classifies steel as 100% environmentally friendly. Conversely, the EPA classifies zinc as a secondary water contaminant, and other environmental agencies cite zinc as a toxin with adverse effects to the environment and our health.

3. Recyclable

For years, the majority of scrap wheel weights have been recycled for use in battery manufacturing. In fact, the vast majority of lead salvaged from recycled wheel weights is used in the production of new car batteries. Recently, however, several ind ustry sources have warned that their recycling programs for wheel weights are in jeopardy due to the multiple metals now found in the recycling stream.

Only steel can be easily and economically separated from lead in the conversion process.

4. Easy Application

We know that it is essential for a wheel weight to be easy to apply. Our engineers are focused on this.and we regularly test the product against competitive products to ensure that delivers the highest-quality and easiest-to-apply wheel weights in the industry.

5. More Cost-Effective

Studies show that steel prices are expected to remain comparatively constant, but zinc and lead prices will most likely continue to be volatile, directly impacting the price you pay for zin cand lead wheel weights.

6.Higher Corrosion Resistance

Shengshiweiye wheel weights are treated with an OE industry-approved metallic coating that enhances the wheel weights’ corrosion resistance and protects wheel appearance. This unique coating will not chip and delivers nearly three times the corrosion resistance than traditional polyester topcoat.

Want to know about Lead Wheel Balance Weight?

For passenger cars, motorcycles and truck wheels, two options are available: clip-on and adhesive wheel weights.

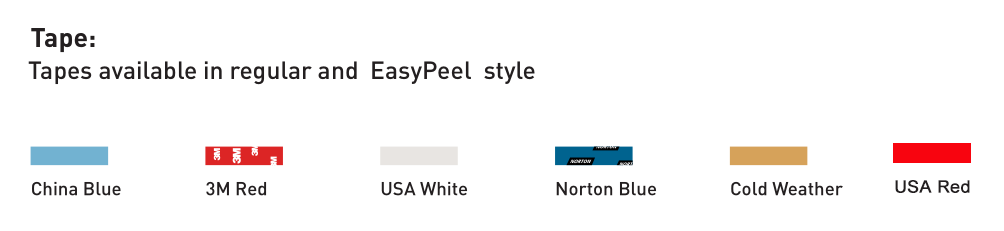

Tape type For Wheel weight

| Blue tape | Base color | |

| Red Tape | Base color |

| 3M Tape | Re-positionable | |

| White Tape | Base color | |

| Norton Tape | Re-positionable | |

| Yellow Tape | Base color |

All type of Clip-on wheel weight

The most common weight for steel wheels, Will fit standard width rim flange thickness passenger car steel wheels with 13”-17” wheel size.

Standard-width rim flange thickness passenger car steel wheels with 13”-17” wheel size.

North American vehicles equipped with alloy rims that were manufactured prior to 1995.

Many brands like Acura, Buick, Chevrolet, Chrysler, Dodge, Infiniti, Isuzu, Lexus, Oldsmobile & Pontiac

Most North American vehicles equipped with alloy rims. The MC-Series is the most sold & installed wheel weight for alloy rims. Many brands like Buick, Chevrolet, Chrys

Many new Ford models, on most European vehicles and certain Asian vehicles equipped with alloy wheels.

Many brands like Audi, BMW, Cadillac, Jaguar, Kia,Nissan, Toyota, Volkswagen & Volvo

Audi, Mercedes-Benz, Volkswagen and very early-model Japanese vehicles equipped with alloy wheels.

Many brands like Acura, Audi, Ford, Honda, Mercedes-Benz & Volkswagen

Most Japanese vehicles equipped with alloy wheels. Application to most Japanese vehicles.

Many brand like Acura, Honda, Infiniti, Lexus, Nissan & Toyota

Clip-on adhesive wheel weight Packing

| Spec | Pcs/BX | BX/CTN | Size(mm) | CTN Size(mm) |

| 5g | 100 | 20 | 115*75*60 | 420x250x130 |

| 10g | 100 | 12 | 135*115*70 | 420x250x150 |

| 15g | 100 | 12 | 135*115*70 | 420x250x150 |

| 20g | 100 | 8 | 135*115*70 | 420x250x130 |

| 25g | 100 | 8 | 195*115*60 | 420x250x130 |

| 30g | 100 | 6 | 225*130*70 | 420x250x150 |

| 35g | 50 | 12 | 135*115*70 | 420x250x150 |

| 40g | 50 | 8 | 195*115*60 | 420x250x130 |

| 45g | 50 | 8 | 195*115*60 | 420x250x130 |

| 50g | 50 | 8 | 195*115*60 | 420x250x130 |

| 55g | 50 | 8 | 195*115*60 | 420x250x130 |

| 60g | 50 | 6 | 225*130*70 | 420x250x150 |

| Spec | Pcs/BX | BX/CTN | Size(mm) | CTN Size(mm) |

| 0.25oz | 100 | 20 | 115*75*60 | 420x250x130 |

| 0.50oz | 100 | 12 | 135*115*70 | 420x250x150 |

| 0.75oz | 100 | 12 | 135*115*70 | 420x250x150 |

| 1.00oz | 100 | 8 | 135*115*70 | 420x250x130 |

| 1.25oz | 50 | 8 | 195*115*60 | 420x250x130 |

| 1.5oz | 50 | 6 | 225*130*70 | 420x250x150 |

| 1.75oz | 50 | 12 | 135*115*70 | 420x250x150 |

| 2.00oz | 50 | 8 | 195*115*60 | 420x250x130 |

| 2.25oz | 50 | 8 | 195*115*60 | 420x250x130 |

| 2.50oz | 50 | 8 | 195*115*60 | 420x250x130 |

| 2.75oz | 50 | 8 | 195*115*60 | 420x250x130 |

| 3.00oz | 50 | 6 | 225*130*70 | 420x250x150 |

Shpping

| Lead time | 3-7day |

| Loading Port: | Xingang Port |

| Qingdao Port | |

| Shanghai Port | |

| Ningbo Port | |

| Shinping method: | By sea For LCL and Full container terms |

| By air For LCL terms | |

| By Truck For Inland transportation |